Design Guide and Engineer’s Reference for Metal Belts

Our team of engineering experts have compiled this Design Guide to help address your design considerations and other questions about PureSteel® metal belts, that may benefit your automated assembly line or manufacturing application. The Design Guide offers design resources and other relevant information in the following areas:

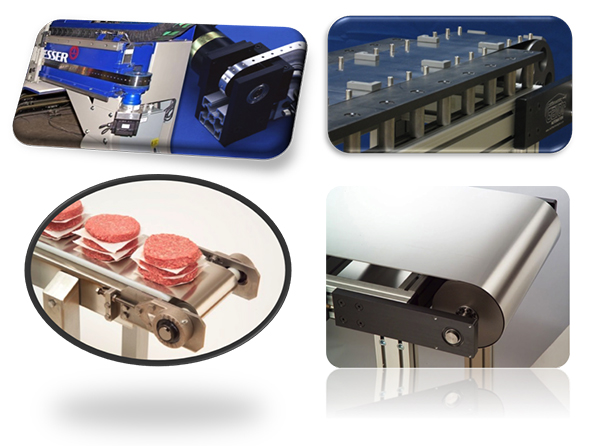

- Why Consider Metal Belts for Your Application?

- Stainless steel belts are often chosen for their durability, resistance to corrosion, smooth operation and more. Learn about the benefits of our PureSteel® products to uncover the ways they could improve your product throughput or quality.

- Metal Belts and Drive Tapes

- Metal belts are endless; drive tapes are open-ended. Learn more about the similarities and differences between the two, and the versatile applications of each.

- Pulleys

- Learn about our pulley types, ranging from more basic friction drive pulley, to timing pulleys. With an array of material types and other, enhanced features, there is a solution to meet your needs.

- Surface Treatments

- Teflon®. Hard Coat Anodization. These are just a few of our available surface treatment options. Learn more about coating, plating, laminating and bonding and how surface treatments can benefit material handling.

- Design Considerations

- Our machine design literature outlines best practices and design considerations for you to implement in your facility.

- Belt Life

- More durable than fabric, rubber or PVC alternatives, PureSteel® stainless steel belts are long-lasting and a sound choice for even the most demanding production operations.

- Metal Belt Materials (Appendix)

We hope this information helps you understand the many benefits of metal belts and gives you the knowledge you need to specify metal belts with confidence.